We transform surplus bark from the timber industry into high‑performance façade and interior panels — bio‑based, durable, VOC‑free, and designed to store carbon.

Bio‑based

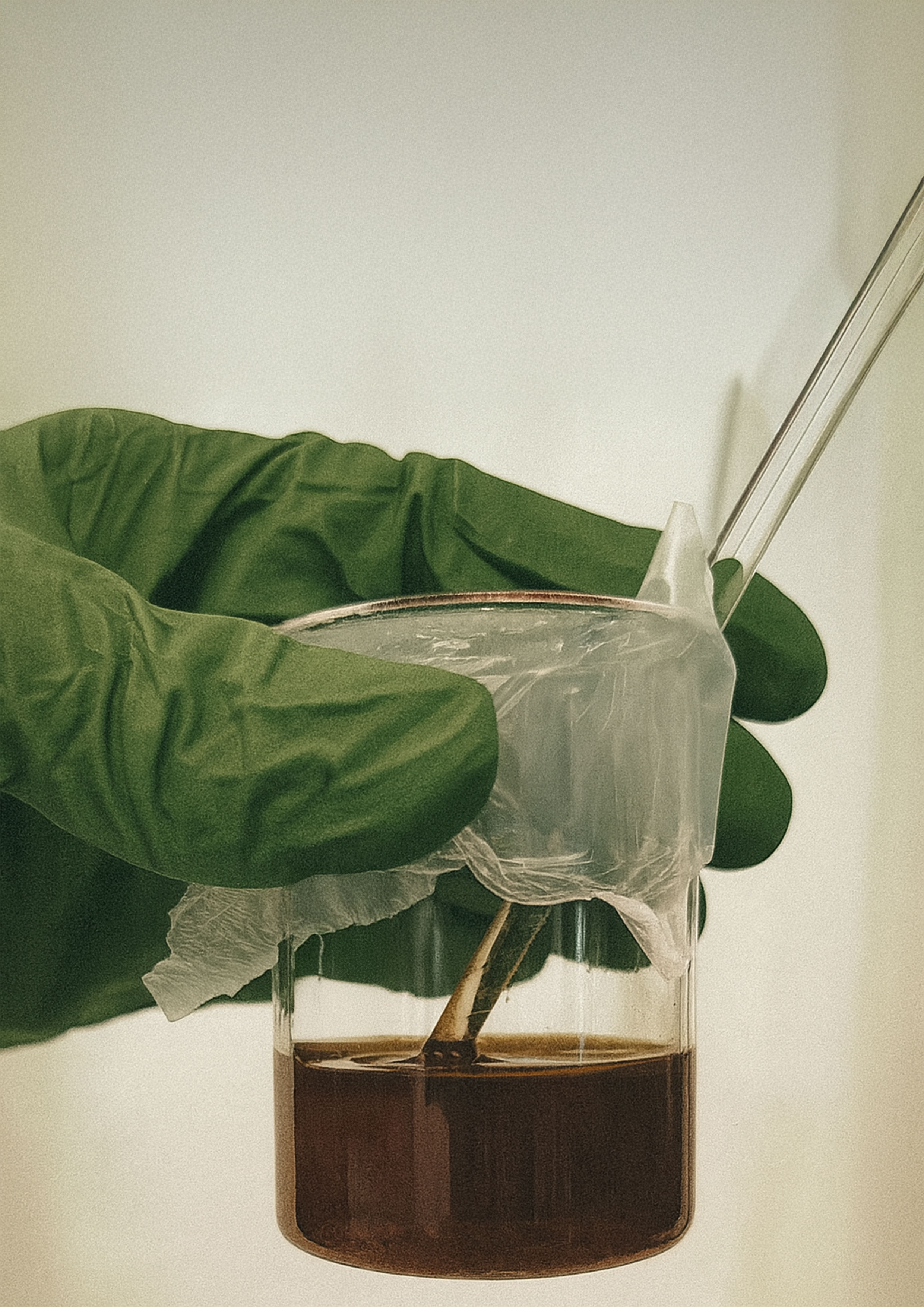

Binder from bark tannins

Carbon‑storing

Locks CO₂ in the material

VOC‑free

Healthier indoor environments

Built for weather

Natural durability & UV resistance

Backed by

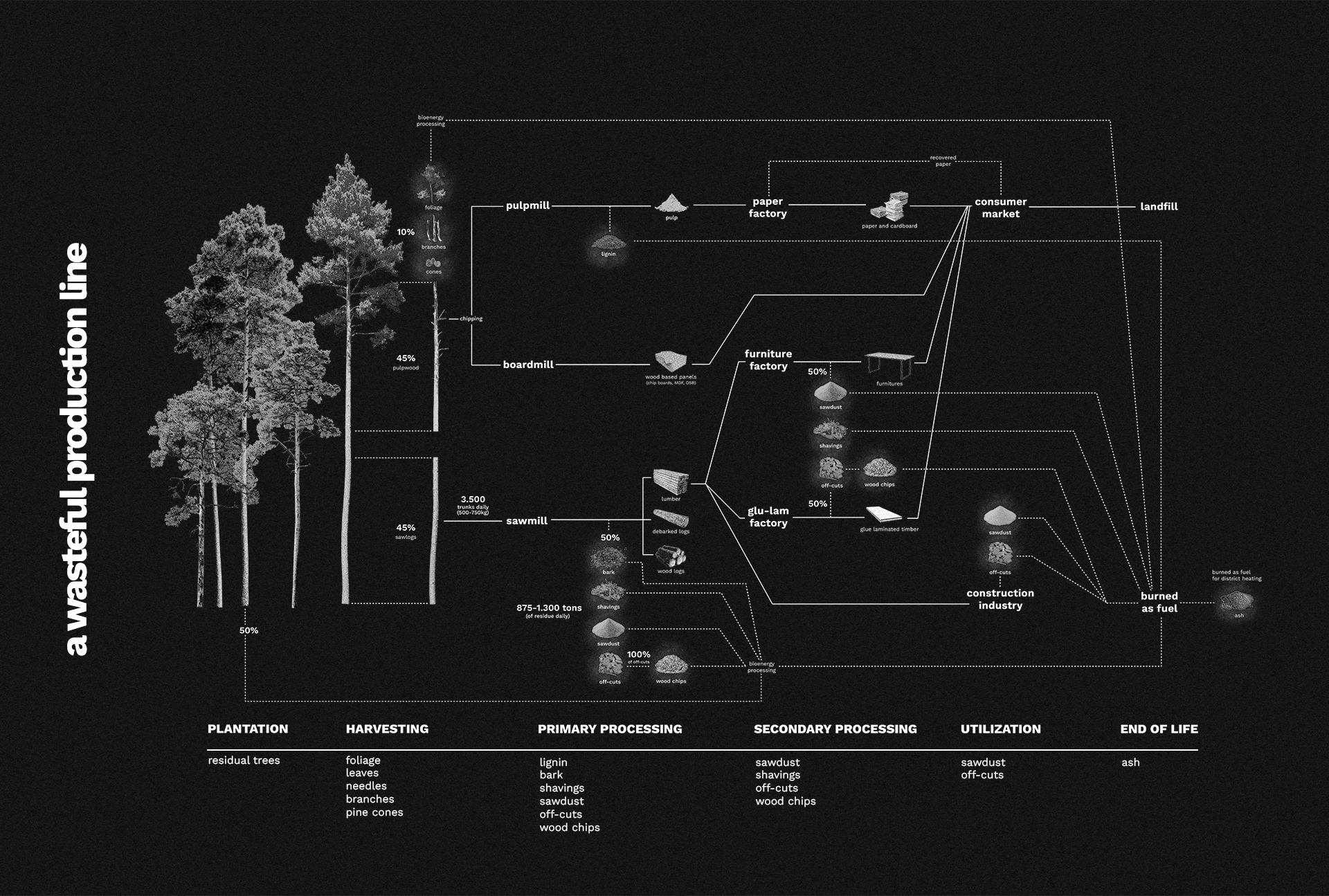

Today, most bark from sawmills is stockpiled and eventually burned despite low fuel efficiency. We reclaim this overlooked stream and turn it into a valuable building component that fits standard construction workflows.

Traditional timber processing creates significant waste streams that are often burned or landfilled, representing both environmental and economic inefficiencies.

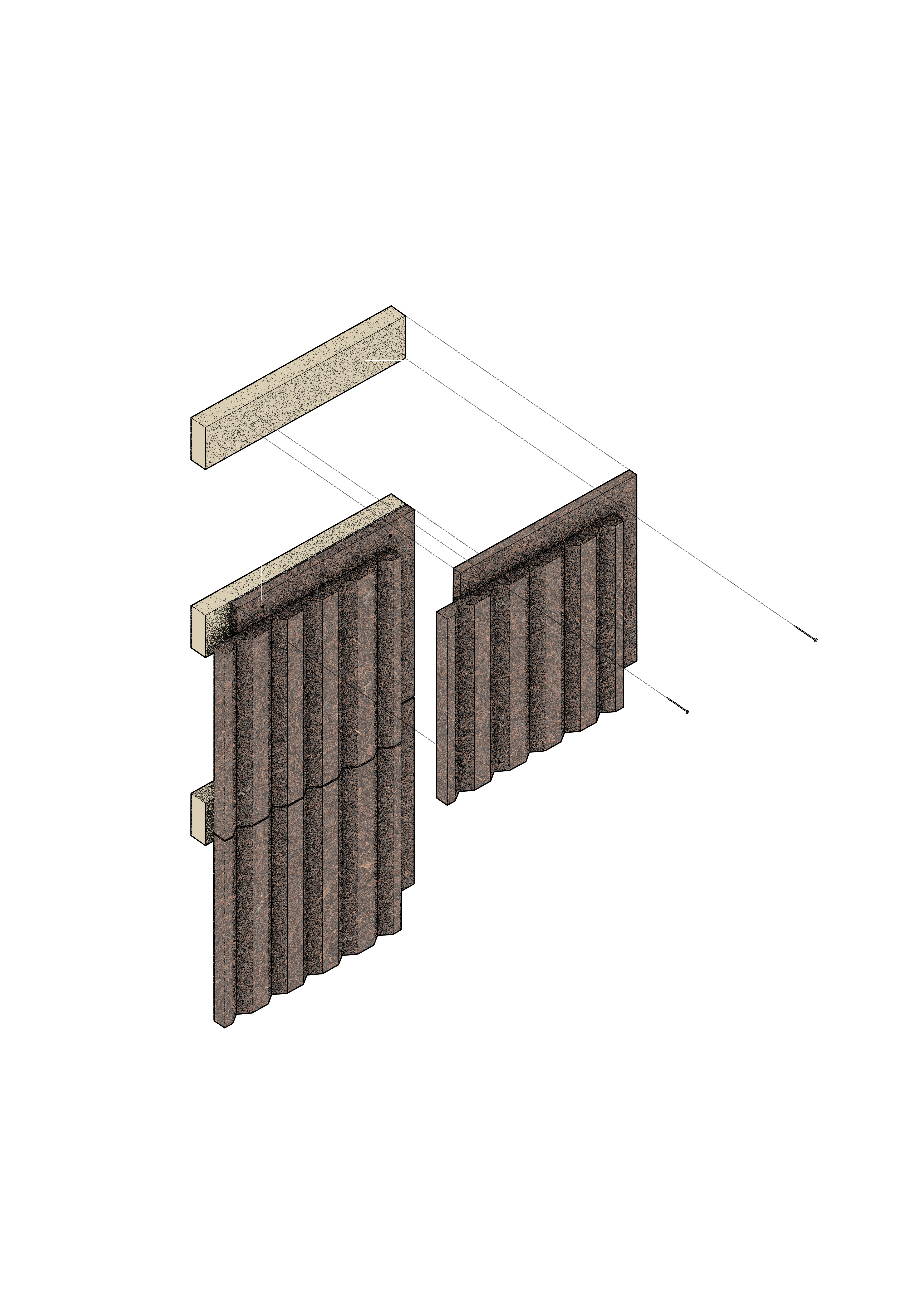

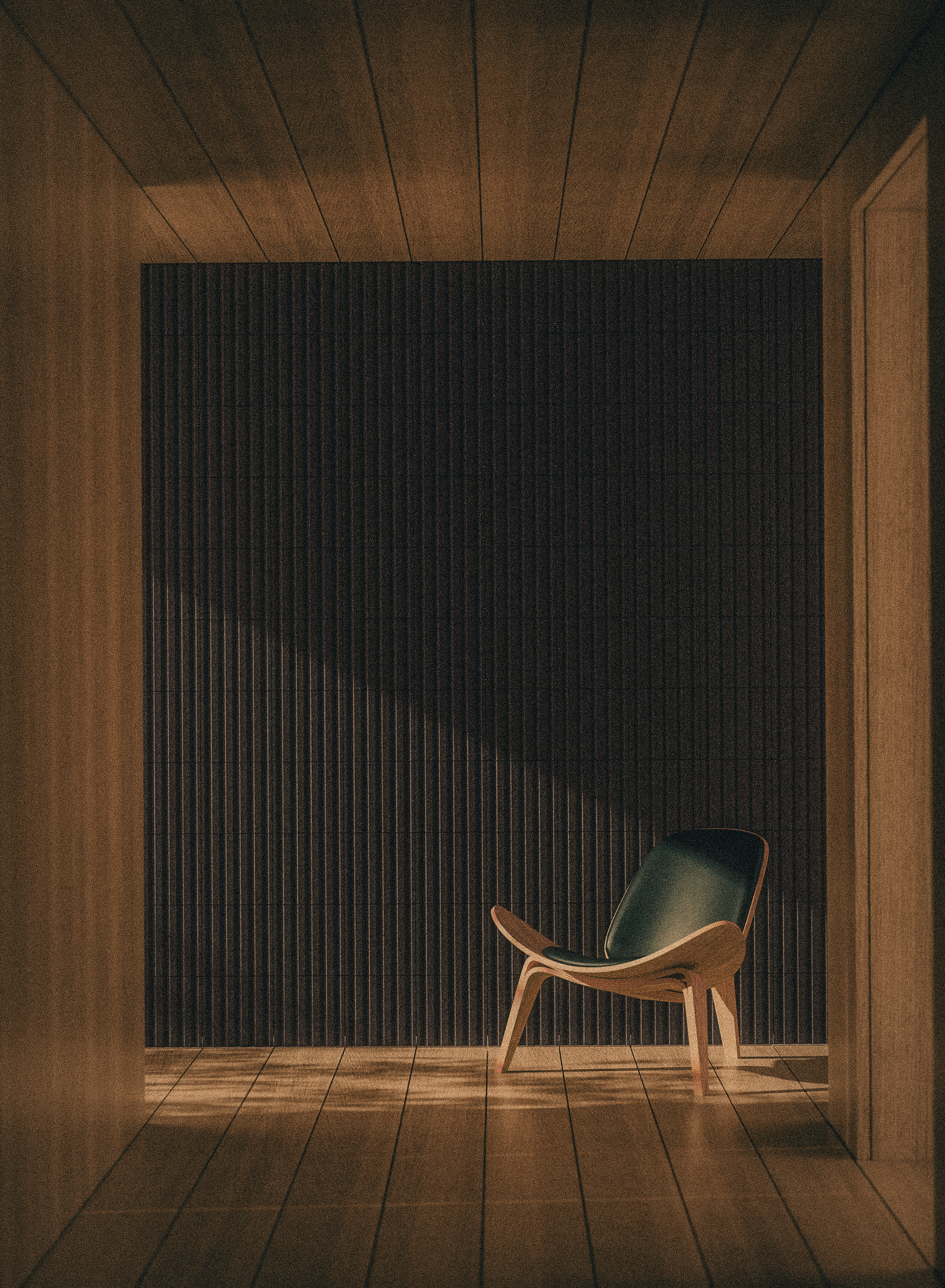

A cladding panel made from surplus bark and our proprietary bio‑based binder. Designed as exterior façade or interior wall panel, with a concealed fastener system and water‑shedding overlap profile.

Concealed fastening

Clean surface with hidden screws

Timber‑system ready

Aligns with standard battens

Outdoor durability

Natural weather & UV resistance

Acoustic comfort

Dense composite helps dampen sound

Our binder is based on tannins extracted directly from the same bark used in our cladding panels, creating a fully integrated material system with multiple functions derived from a single natural resource.

Natural Tannin Foundation

Bark naturally contains tannins, plant-based polyphenols that form the foundation of our binder system, engineered for strong adhesion, dimensional stability, and resistance to moisture and fire.

Circular Material Logic

This approach minimizes external inputs and maximizes the potential of an overlooked byproduct, resulting in a high-performance, bio-based composite where both structure and binder originate from the same raw material.

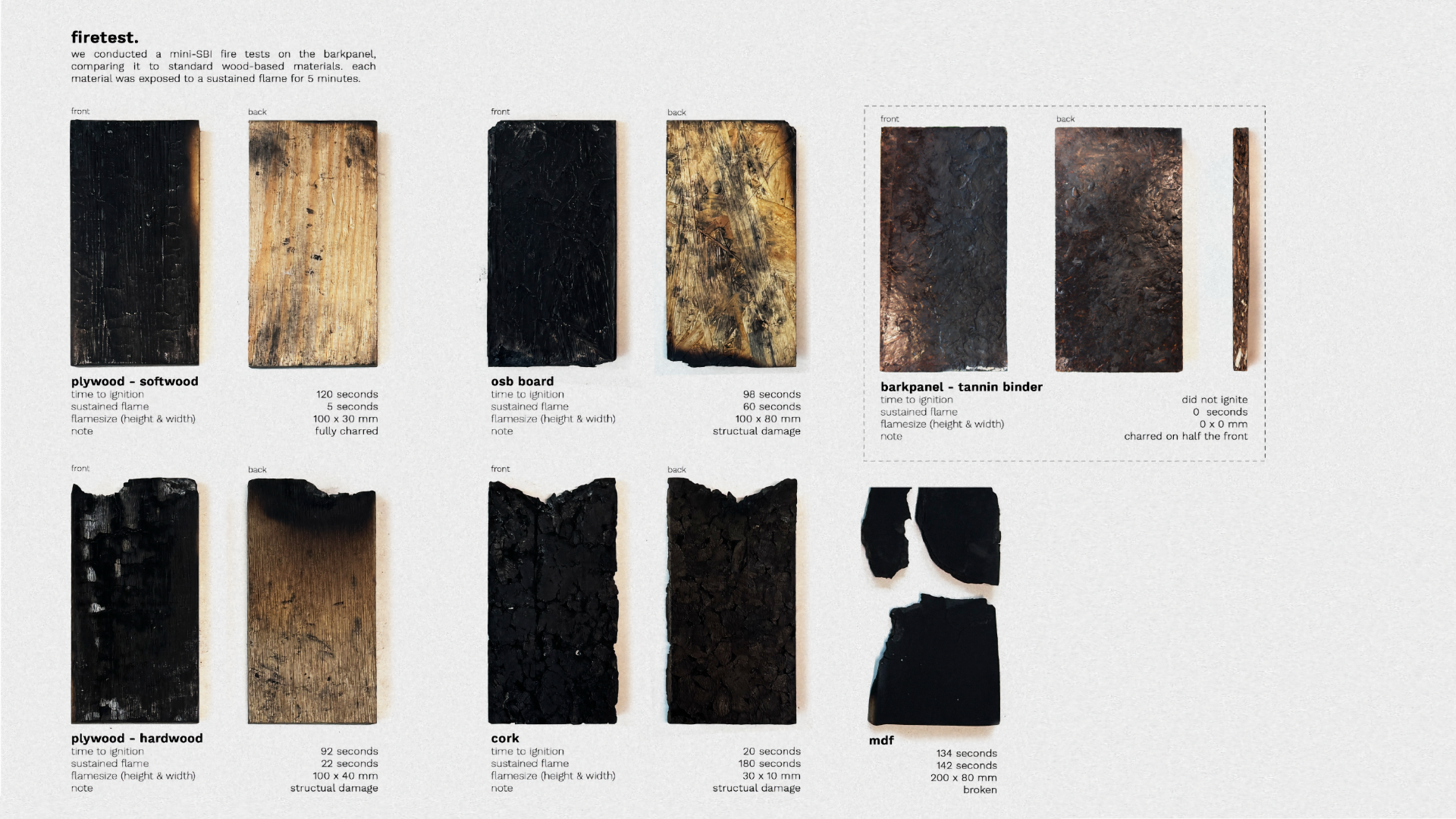

Validated Performance

The binder has been validated through fire testing and durability studies, is being refined for final certifications, and represents a step forward in low-impact materials for the built environment.

Bio‑based & VOC‑free

Binder derived from bark tannins; no formaldehyde or isocyanates.

Carbon‑storing

Locks CO₂ and reduces embodied emissions compared to conventional panels.

Circular by design

Single source material logic supports end‑of‑life recovery.

Aesthetic quality

A natural, tactile surface that ages with dignity.

*Values reflect pilot targets and ongoing certification.

From innovation to commercialization - our roadmap to sustainable building materials

Pilot Production

2025

Building our first production line

Pilot Installations

Q4 2025 – Q1 2026

Pilot installations in various contexts

Certification

Q4 2025 – Q2 2026

Meeting industry standards

Commercial Launch

From 2026

Scaling commercial operations

Our proprietary bio‑based binder, developed in‑house, is 100% biodegradable and derived from natural bark tannins. This innovative approach eliminates the need for traditional petroleum‑based binders while maintaining exceptional material performance.

Promising Fire Test Results

Initial fire resistance testing shows excellent performance, indicating strong potential for achieving our target fire class B‑s1,d0 certification.

Sustainable Innovation

Our binder technology represents a breakthrough in sustainable building materials, combining environmental responsibility with fire safety performance.

Aarhus Ø

Construction install — Q4 2025

Demonstration — Aarhus

Awaiting pilot production

Smart Buildings

Awaiting pilot production

Villa (private)

Installation Q4 2025

Incuba - Reception

Installation Q4 2025

Interior wall (private)

Installation Q1 2026

Interested in pilot projects, specifying the barkpanel, or partnering on production? Get in touch.

Inge Lehmanns Gade 10, 6. sal, 8000 Aarhus C, Denmark